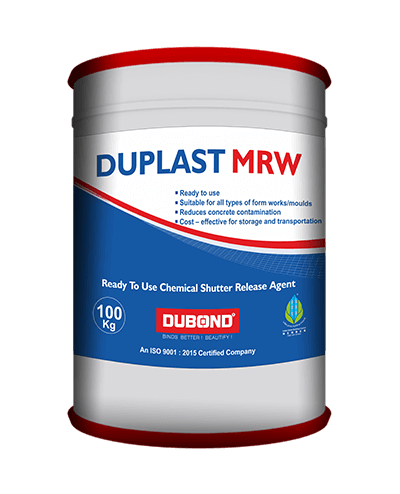

Duplast MRO is a concentrated emulsified chemical mould, release oily liquid. It is pale amber liquid carefully blended combination of refined emulsified mineral oil and chemical release agents. It is used for easy – stain free release of concrete moulds and formwork of all types. It has an outstanding releasing properties and advantages over conventional oil. It may react with the alkali in the concrete to form a thin water repellent skin on the surface of the mould which enables easy strapping from the hardened concrete.

Duplast MRO

- Ready to use

- Non-staining concrete surfaces

- Suitable for all types of form works/moulds

- Fast and easy – strapping

- Increased life of form work

- Reduces concrete contamination

- Gives fair- faced concrete finish

- Economical and easy to use

- Cost – effective for storage and transportation

First dilute Duplast MRO in the proportion of 1litre to 5litre of water using a clean container on stirring thoroughly until evenly mixed. If the solution is not used on the same day it should be stirred again before use. Apply the solution to the face of the formwork by spray brush or cloth, only one coat should be applied (as thinly as possible) and allow it to dry. If the form worm work is not used for several days then only, apply a further coat.

- 18 to 20 m² per litre is possible depending upon the porosity and texture of surface.

- Ensure good ventilation and do not smoke during use. Its Flash point is 60°C.

- Form : Liquid

- Colour : Pale Liquid

- Dilution Rate : 1:5 with water

- Specific Gravity : 0.85 ± 0.02 at 27º C

- Duplast MRO has a storage life of 1 year, if stored under 50°C in unopened condition.

- Diluted product should be used within 5 days.

Advantage & Benefits

Advantage & Benefits Method of Use

Method of Use Coverage

Coverage Technical Data

Technical Data Storage Life

Storage Life